- 差分压力:

- 0 .. 20.68 mbar up to 0 .. 1034 mbar

- 相对压力/表压:

- 0 .. 20.68 mbar up to 0 .. 1034 mbar

- 绝对压力:

- 0 .. 1034 mbar

主要参数

|

压力范围* |

差分压力: |

0 .. 20.68 mbar --> 0 .. 1034 mbar |

|

相对压力/表压: |

0 .. 20.68 mbar --> 0 .. 1034 mbar |

|

|

绝对压力: |

0 .. 1034 mbar |

|

|

mV级比例电压输出 |

0 .. 25.0 mV |

低压范围 (≤ 206.8 mbar) |

|

0 .. 40 mV |

标准压力范围 (≥ 344.7 mbar) |

|

|

非线性,迟滞,重复性 |

0.3 %FSO (typ.) |

|

|

工作电压 (VS) |

10 V (典型), 20 V (最大) |

|

|

封装形式 |

电路板安装式,陶瓷基板底座,双立直插式DIP-08(宽:0.6英寸) |

|

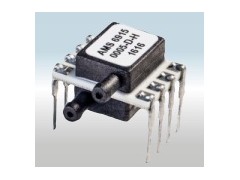

FEATURES

• Calibrated and temperature compensated pressure sensor, fully analog

• Differential, gage / relative and absolute versions

• Standard and low pressure types (ranges from 0 .. 0.3 PSI up to 0 .. 15 PSI)

• Unamplfied ratiometric mV-output signal -typ. 25 mV FSO for low pressure types -typ. 40 mV FSO for standard pressure types

• Constant voltage excitation up to 20 V

• 0 .. 60 ºC compensated temperature range

• High performance, stable silicon chip

• Dual in-line package (DIP)

• REACH and RoHS compliant

GENERAL DEscriptION

AMS 5612 is a series of unamplified, laser trimmed pressure sensors with differential, ratiometric mV output signal. They are designed for constant voltage excitation with a supply voltage up to 20 V. All AMS 5612 are calibrated and temperature compensated within a range of 0 .. 60 °C.

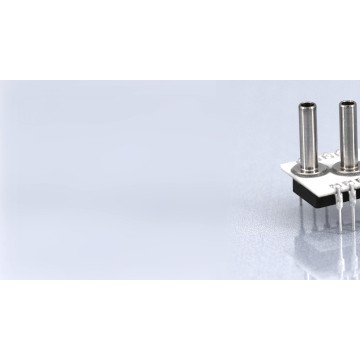

AMS 5612 comes as a dual in-line package (DIP) for assembly on printed circuit boards (PCBs). The electrical connection is made via the DIP solder pins; pressure is connected via vertical metal tubes.

The AMS 5612 series uses micromachined high quality piezoresistive silicon pressure sensor chips in a ceramic package. The calibration of offset and span as well as temperature compensation is done individually during the manufacturing process by laser trimming of thick film resistors. The fully analog construction of this series enables precision, high speed measurements combined with an excellent long-term stability.

TYPICAL APPLICATIONS

• Industrial control

• Medical equipment

• Respiration control

• Level detection

• Flow measurement

• Barometric pressure measurement

• Vacuum monitoring

• Heating, Ventilation and Air Conditioning (HVAC)

第5年

第5年

AM400 电压电流二路平行输出的变送

AM400 电压电流二路平行输出的变送

CAV424 单一或差动电容式信号转换电

CAV424 单一或差动电容式信号转换电

AM417 精密比例电压仪表放大变送集

AM417 精密比例电压仪表放大变送集

AMS5915数字信号I2C输出的OEM压力传

AMS5915数字信号I2C输出的OEM压力传

AM452 差分信号电压电流转换变送集

AM452 差分信号电压电流转换变送集

AMS5935 -18 bit I2C高精度微压压力

AMS5935 -18 bit I2C高精度微压压力

手机图页网

手机图页网