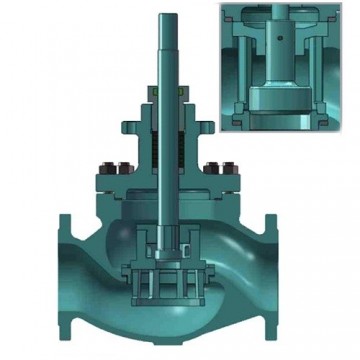

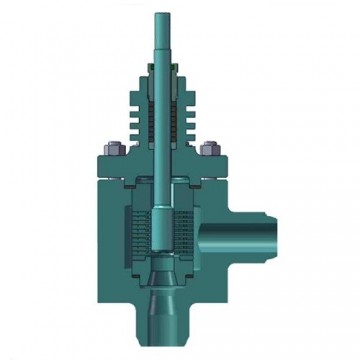

Cryogenic Globe Control Valves are designed to manage the flow of gases and liquids at ultra-low temperatures, often as low as -198°C (-325°F). These valves are built from high-strength materials such as stainless steel, ensuring they can withstand the extreme conditions typical of cryogenic environments.

Typically featuring a globe-style, single-port design, these valves are perfect for precise throttling or on/off control of cryogenic fluids, offering exceptional flow control at very low temperatures. The design allows for smooth operation and accurate regulation of fluid flow, essential for maintaining the stability and safety of processes in cryogenic applications.

These valves are equipped with specialized packing systems that ensure enhanced stem sealing, preventing leaks and maintaining the integrity of the process fluid, even in harsh conditions. This advanced sealing technology also extends the life of the valve, reducing the need for frequent maintenance.

Cryogenic globe control valves are engineered with seats designed to provide reliable shutoff in extreme temperatures. The robust seat design ensures long-lasting performance, reducing wear and tear and contributing to lower maintenance costs over time.

These valves are widely used in critical applications such as air separation and LNG (Liquefied Natural Gas) plants, where high safety standards and consistent performance are paramount. Designed to meet stringent industry regulations, they offer reliable, efficient operation for industrial gas processing, supporting a range of applications where precision and safety are key.Gotta know about Google SEO.

第1年

第1年

Actuated Control Valve

Actuated Control Valve

Skirt Control Valve

Skirt Control Valve

Pneumatic Control Valve

Pneumatic Control Valve

Wafer Control Valve

Wafer Control Valve

Aluminium Control Valve

Aluminium Control Valve

Pressure Relief Control Valves

Pressure Relief Control Valves

Pneumatic Control Valve

Pneumatic Control Valve

Cut-off Control Valve

Cut-off Control Valve

Caged Control Valve

Caged Control Valve

Labyrinth Control Valve

Labyrinth Control Valve

手机图页网

手机图页网