Ultrasonic Switches

Ultrasonic switches are a cost-effective solution for your applications. Installation requires

mounting the sensor (threaded or flanged) to the vessel, connecting the power and control wires,

and applying power. There is no additional set-up or calibration required. Since it is an electronic instrument with no moving parts, preventive maintenance is limited to an annual visual

inspection. The only recommended spare part is the “board” at a quantity of one board for every

10 units. A technician with basic electrical skills (wiring) can service the instrument.Why use an ultrasonic switch ove

mounting the sensor (threaded or flanged) to the vessel, connecting the power and control wires,

and applying power. There is no additional set-up or calibration required. Since it is an electronic instrument with no moving parts, preventive maintenance is limited to an annual visual

inspection. The only recommended spare part is the “board” at a quantity of one board for every

10 units. A technician with basic electrical skills (wiring) can service the instrument.Why use an ultrasonic switch ove

更多详情

Ultrasonic Switches

Ultrasonic switches are simple to apply and use. There are only a few limitations to their use:

The media must be liquidProcess temperature between -40 and 250oF (-40 to 121oC)

The media must have less than 5% suspended solids

No aeration in fluids with a viscosity of 100cP (30W motor oil) or greater

The following chart will assist you in selecting the right product for your application.

cription="" style="margin: 0px; padding: 0px; border: 0px; line-height: 1; font-family: inherit; max-width: 100%; vertical-align: middle;" />

cription="" style="margin: 0px; padding: 0px; border: 0px; line-height: 1; font-family: inherit; max-width: 100%; vertical-align: middle;" />

第6年

第6年

Mechanical Level Switches

Mechanical Level Switches

超纯水测量PH电极 纯水测量PH电极

超纯水测量PH电极 纯水测量PH电极

工业污水复合PH电极 工业污水PH电极

工业污水复合PH电极 工业污水PH电极

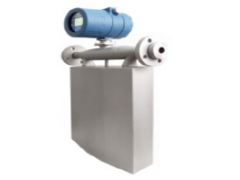

分体式电磁流量计

分体式电磁流量计

KYF 系列微小流量计

KYF 系列微小流量计

高精度数字压力表

高精度数字压力表

一体化差压变送器

一体化差压变送器

手机图页网

手机图页网